| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : HT

Model Number : Alloy Steel 31

Certification : ISO SGS BV TUV CE,etc.

Place of Origin : China

MOQ : 1pc

Price : Negotiation

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 1000000000pcs per month

Delivery Time : 1~15days

Packaging Details : plywood case,pallet,etc.

Type : Socket Weld Flange

Standard : DIN,ANSI,ASME,JIS,GB

Material : Alloy 31

Size : 1"-4"

Pressure : 300#-2500#

Process : CNC Processing,Casting,forged

Application : Power generation,gas and oil pip,Pipe Tube Connection,Chemical and petrochemical,Industry

Sample : For free,Avaliable,but you need to pay for the freight charge for the samples

Socket Weld Nickel Alloy Flanges Alloy 31 ASTM B564 UNS N08031 1/2 Inch - 24 Inch

1. ALLOY 1.4562 / UNS N08031 / ALLOY 31

Corresponding Standards: EN 1.4562, UNS N08031 MATERIAL DESCRIPTION

• Alloy 31 is a nickel, chromium and molybdenum stainless steel with nitrogen and copper additions. It combines moderate tensile strength and high ductility with excellent corrosion resistance in sulfuric acid, reducing and oxidizing media and has strong resistance to corrosion and erosion corrosion in phosphoric environment.

• Typically the alloy has PREN of ≥ 48, which ensure that the resistance to pitting corrosion is high.

CHEMICAL COMPOSITION

| WEIGHT% | C | SI | MN | S | P | CR | NI | MO | N | CU |

| MIN. | 26,0 | 30,0 | 6,0 | 0,15 | 1,0 | |||||

| MAX. | 0,015 | 0,3 | 2,00 | 0,010 | 0,020 | 28,0 | 32,0 | 7,0 | 0,25 | 1,4 |

PREN = (CR% + 3.3MO% + 16N%) ≥ 48

PRODUCT STANDARDS: ASTM B625 – 14

APPROVALS: FOR USAGE IN PRESSURE VESSELS WITH WALL TEMPERATURES BETWEEN -196°C TO 550°C

APPLICATIONS

Typical applications: Pulp and paper industry, flue gas desulphurization – FGD – systems, sea water heat exchangers, petroleum production and refining industry, mining industry – ore processing…

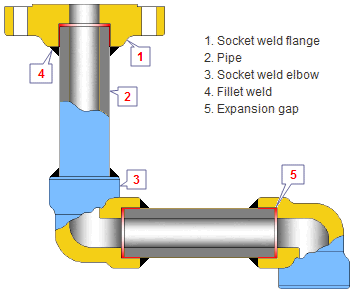

2. SOCKET WELD PIPE FLANGES

Socket-weld pipe flanges are typically used on smaller sizes of high pressure pipes. These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. Slip on Pipe flanges with a hub have published specifications that range from 1/2" thru 24". Coastal Flange provides Socket Weld pipe flanges in all material grades, specifications and sizes.

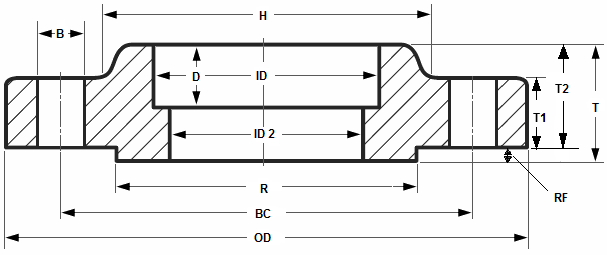

Socket Weld Flange Dimensions

ASME B16.5 Class 150

| SIZE | ID | OD | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | H | D | ID 2* | Raised Face Thickness (T) | T1 | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2" | 0.88" | 3.50" | 2.38" | 1.38" | .063" | 1.19" | .38" | 0.62" | .62" | .38" | .56" | .62" | 4 |

| 3/4" | 1.09" | 3.88" | 2.75" | 1.69" | .063" | 1.50" | .44" | 0.82" | .62" | .44" | .56" | .62" | 4 |

| 1" | 1.36" | 4.25" | 3.12" | 2.00" | .063" | 1.94" | .50" | 1.05" | .69" | .50" | .63" | .62" | 4 |

| 1-1/4" | 1.70" | 4.62" | 3.50" | 2.50" | .063" | 2.31" | .56" | 1.38" | .81" | .56" | .75" | .62" | 4 |

| 1-1/2" | 1.97" | 5.00" | 3.88" | 2.88" | .063" | 2.56" | .62" | 1.61" | .88" | .62" | .82" | .62" | 4 |

| 2" | 2.44" | 6.00" | 4.75" | 3.62" | .063" | 3.06" | .69" | 2.07" | 1.00" | .69" | .94" | .75" | 4 |

| 2-1/2" | 2.94" | 7.00" | 5.50" | 4.12" | .063" | 3.56" | .75" | 2.47" | 1.12" | .82" | 1.06" | .75" | 4 |

| 3" | 3.57" | 7.50" | 6.00" | 5.00" | .063" | 4.25" | .81" | 3.07" | 1.19" | .88" | 1.13" | .75" | 4 |

| 3-1/2" | 4.07" | 8.50" | 7.00" | 5.50" | .063" | 4.81" | .88" | 3.55" | 1.25" | .88" | 1.19" | .75" | 8 |

| 4" | 4.57" | 9.00" | 7.50" | 6.19" | .063" | 5.31" | .94" | 4.03" | 1.31" | .88" | 1.25" | .75" | 8 |

| 5" | 5.66" | 10.00" | 8.50" | 7.31" | .063" | 6.44" | .94" | 5.05" | 1.44" | .88" | 1.38" | .88" | 8 |

| 6" | 6.72" | 11.00" | 9.50" | 8.50" | .063" | 7.56" | 1.06" | 6.07" | 1.56" | .94" | 1.50" | .88" | 8 |

| 8" | 8.72" | 13.50" | 11.75" | 10.62" | .063" | 9.69" | 1.25" | 7.98" | 1.75" | 1.06" | 1.69" | .88" | 8 |

| 10" | 10.88" | 16.00" | 14.25" | 12.75" | .063" | 12.00" | 1.31" | 10.02" | 1.94" | 1.13" | 1.88" | 1.00" | 12 |

| 12" | 12.88" | 19.00" | 17.00" | 15.00" | .063" | 14.38" | 1.56" | 12.00" | 2.19" | 1.19" | 2.13" | 1.00" | 12 |

| 14" | 14.14" | 21.00" | 18.75" | 16.25" | .063" | 15.75" | 1.63" | 13.25" | 2.25" | 1.32" | 2.19" | 1.12" | 12 |

| 16" | 16.16" | 23.50" | 21.25" | 18.50" | .063" | 18.00" | 1.75" | 15.25" | 2.50" | 1.3 |

3. Advantages and disadvantages of Socket Weld fittings

The pipe need not be beveled for weld preparation. Temporary tack welding is no needed for alignment, because in principle the fitting ensures proper alignment.

The weld metal can not penetrate into the bore of the pipe.

They can be used in place of threaded fittings, so the risk of leakage is much smaller. Radiography is not practical on the fillet weld; therefore correct fitting and welding is crucial. The fillet weld may be inspected by surface examination, magnetic particle (MP), or liquid penetrant (PT) examination methods.

Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation.

|

|

Socket Weld Nickel Alloy Flanges Alloy 31 ASTM B564 UNS N08031 1/2 Inch - 24 Inch Images |